Plant report: how an Actros becomes an Edition 2

Report

A premium Actros in the making: Mercedes‑Benz Trucks has even reserved an assembly area especially for the Edition 2.

One instrument panel after the other hangs over the production line. Here in the Mercedes‑Benz Wörth plant, the production-line employees know exactly what to do when. Step‑by‑step they work through the equipment in the cockpit with the help of a list. The instrument panel which is up next looks visibly different to the others – for a start, it’s covered with a beige-coloured cover. And what’s underneath is reminiscent of the S‑Class. Mercedes‑Benz Trucks has covered it with black nappa leather. Various interior parts come in a carbon-fibre look. And it’s already clear that in the next few hours, a special truck will be born on this production line.

The Actros Edition 2 special model is limited to 400 units and has everything it needs to be the truck flagship over the coming years.

Here everything is done by hand.

The row of cabs in the cab interior fittings section provides for a colourful assembly line. In this production stage too, one of the cabs in particular stands out. A special decal with the so-called “star pattern” between the B and C pillar is visible.

Everything that is carried out on this assembly line is done by hand. If this weren’t the case, it would not be possible to handle the sheer quantity of possible equipment options and work steps. On the Edition 2 for example, the nappa leather instrument panel is now being fitted. It is only one of many features in the Edition interior. The truck will be equipped with such appointments as a high-quality leather steering wheel, leather door handles with topstitching and a roof hatch equipped with ambient lighting.

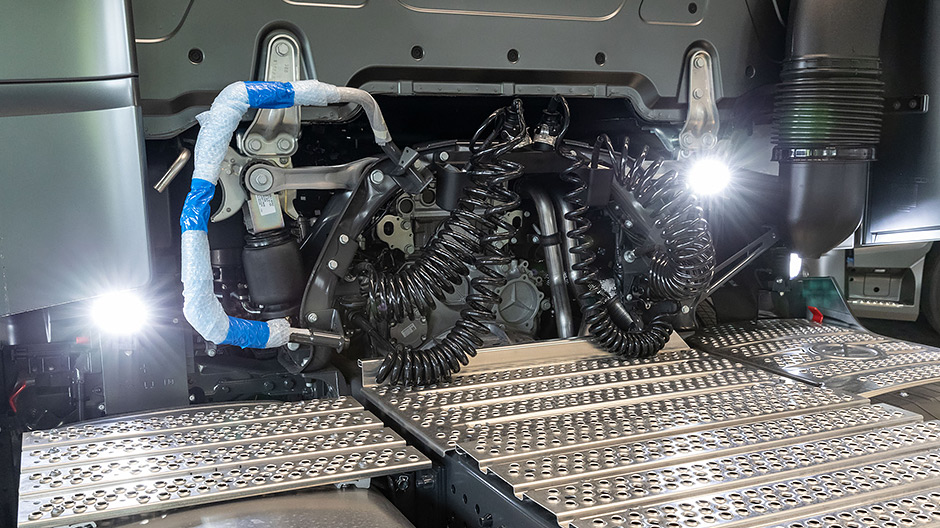

It takes around six hours for all of the equipment to be installed in the truck’s cab. Then the cab – shown here with magno cerussite grey paint – is fitted to the chassis, where it thrones above an extremely powerful 12.8‑litre six-cylinder engine with an output of 390 kW.

This article contains additional material (videos, images and reports etc.) for registered RoadStars members. In order to experience the article to the full, you need to log in with your RoadStars account or register for one free of charge.

Become a RoadStar and gain access to exclusive content and campaigns!

Login for RoadStars members

Not yet a member? Join RoadStars now

Obtain exclusive access to exciting events and activities which only RoadStars can offer.

Join RoadStarsReady for the finishing touches.

Once the Actros leaves the assembly line, an employee drives it to the roller dynamometer on its own wheels. All driving functions and assistance systems are checked, the tachometer is calibrated and the engine’s performance is tested. Then, the visual inspection takes place in the light tunnel. Only then is the Actros allowed to leave the production hall, where it is then ready for its finishing touches to become an Edition 2.

This takes the special model into an area of hall 16. Another eleven trucks are waiting inside for tuning. Eleven members of staff ensure that the truck is given its “wow” effect. One of those colleagues is Dominic Rutgers. “Here we carry out all of the special installations that aren’t possible on the production line as it would simply take too much time to do it any other way.” says the process mechanic who otherwise works in the final assembly section in the plant. In a section of the hall, a workshop has been set up. For six months Dominic Rutgers and the other ten selected colleagues are giving 400 Actros trucks the very finest plant tuning. It takes around a day’s work for the staff to complete that for each truck.

No matter whether its the decals on the side trim, the wiring for the four additional headlamps in the special Edition sun visor or the stainless steel axle caps and the aluminium steps in the side panelling – small teams work on the individual features, one after another. Standard components are removed and luxury parts installed in their place. “The plastic steps up to the cab, for example, get replaced with stainless steel steps.” Plus numerous other visual details are added on both the inside and outside, including the “Edition 2” logo or the illuminated emblem in the entrance.

Dominic Rutgers finds the Edition 2 “star pattern” decals the ultimate highlight among all of the equipment. “I am proud to be involved,” he says as he touches the small stars. “I’m particularly looking forward to seeing one of these vehicles out on the road.”

Photos: Henrik Morlock

Video: Martin Schneider-Lau

Comment

Please log in to post a comment.

34 comments

à refaire

à refaire

They will be able to offer you advice on specifying the vehicle.

They will be able to offer you advice on specifying the vehicle.

Wenn du dich bei einer zukünftigen Gelegenheit vorab informieren lassen möchtest, dann nimm einfach Kontakt zu dem Händler in deiner Nähe auf: https://www.mercedes-benz-trucks.com/de_DE/buy/dealer-locator.html

Solltest du Interesse an einem Nicht-Neufahrzeug haben, könntest du beispielsweise online bei TruckStore nachschauen https://www.truckstore.com/DE/de/home.html oder dich ebenfalls vom Händler in deiner Nähe beraten lassen. 😊

Wenn du dich bei einer zukünftigen Gelegenheit vorab informieren lassen möchtest, dann nimm einfach Kontakt zu dem Händler in deiner Nähe auf: https://www.mercedes-benz-trucks.com/de_DE/buy/dealer-locator.html

Solltest du Interesse an einem Nicht-Neufahrzeug haben, könntest du beispielsweise online bei TruckStore nachschauen https://www.truckstore.com/DE/de/home.html oder dich ebenfalls vom Händler in deiner Nähe beraten lassen. 😊

Felicitaciones RoadStars que buen trabajo

Felicitaciones RoadStars que buen trabajo

Und ein marktführender Hersteller, der auch auf die Bedürfnisse der Fahrer eingeht!

Und ein marktführender Hersteller, der auch auf die Bedürfnisse der Fahrer eingeht!

Wie sagt man so schön, "Schwoba-power"👍

Glaub ich bringe meinen noch nachträglich zurück um ihn nachträglich auch zu einen efelen Einzelstück fertigen zu lassen 🤭🤭😋😋

Wie sagt man so schön, "Schwoba-power"👍

Glaub ich bringe meinen noch nachträglich zurück um ihn nachträglich auch zu einen efelen Einzelstück fertigen zu lassen 🤭🤭😋😋

Und schön, dass dir dein neues Fahrzeug so gefällt. Poste gerne viele Bilder deines Schätzchens auf unserer Pinnwand 😉

https://roadstars.mercedes-benz-trucks.com/de_DE/community/2015/june/show-off-your-truck.html

Und schön, dass dir dein neues Fahrzeug so gefällt. Poste gerne viele Bilder deines Schätzchens auf unserer Pinnwand 😉

https://roadstars.mercedes-benz-trucks.com/de_DE/community/2015/june/show-off-your-truck.html

Top!!! 👍🏼👍🏼👍🏼👍🏼👍🏼👍🏼👍🏼👍🏼⛟😎

Top!!! 👍🏼👍🏼👍🏼👍🏼👍🏼👍🏼👍🏼👍🏼⛟😎