The new Actros 1843 LS with tipper body at work for the Geiger Group

Vehicle & Technology

Always something new from Mercedes-Benz Trucks: while the Actros 1843 LS with its hydraulically powered tipping body is built for the road where it performs with its usual efficiency, it can easily handle detours over the rough at construction sites. The Geiger Group in Germany’s Allgäu region already operates the truck with the great payload advantage on a daily basis.

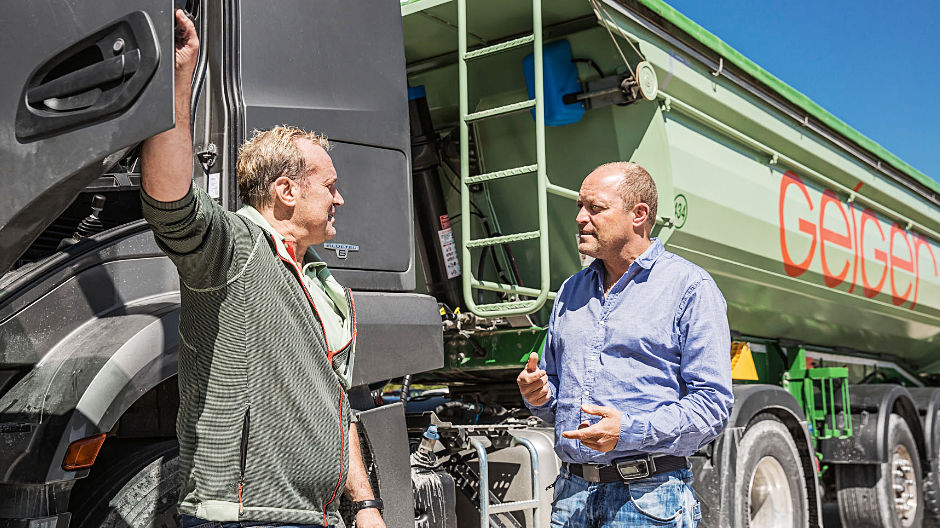

“We want a vehicle that performs very economically on the road but that can also handle the last few metres at the construction site,” says Andreas Weber. He is Head of Logistics and Business Development at the Geiger group of companies, based in the Allgäu region. The solution for the special task at Geiger: the new road-oriented semitrailer Actros 1843 LS with hydraulically-operated tipper body. A glance at the portfolio of the Geiger Group shows that the company operates as comfortably on motorways as on the rough terrain of a construction site.

Founded in 1923 by Wilhelm Geiger and having evolved into a group of companies, the business today offers every service associated with construction projects. From transportation and delivery of materials via project planning, construction and civil engineering right through to renovations and the disposal of materials, Geiger today is a one-stop shop. It makes the Group with a workforce of 2 000 at 50 locations and a turnover of 400 million euros one of the Allgäu region’s biggest employers.

Hauling bitumen from Ingolstadt to Kempten in the Allgäu on the motorway is as much a part of the daily business as carrying bulk freight up and down steep quarry ramps – and it is usually all done by the same green and red coloured fleet of vehicles.

Working on one of the Geiger Group’s smaller projects, the removal of gravel from Lake Forggen, located at the foot of Neuschwanstein Castle and drained for several weeks each year, the road-oriented Actros 1843 LS shows what it is made of. The truck handles approaches down to the front-end loader in the middle of the lakebed with ease. The truck’s improved capability for handling construction site terrain makes the vehicle’s deployment at the interface between motorway and construction site much more efficient and easier to plan for Geiger.

“It is important for us that the long-haul trucks can also handle the odd detour into a construction site.”

Andreas Weber, Head of Logistics and Business Development at Geiger Logistik GmbH & Co. KG in Germany’s Allgäu region

Previously the Actros – built for driving long distances on sealed roads – was not always able to drive onto construction sites. The off-road capable Arocs had to be deployed instead, but its robust design meant lower payloads. The road-oriented Actros 1843 LS prime mover with hydraulically-operated tipper body has now closed this gap.

What matters for Andreas Weber: “The truck must have a very low tare weight so that it can carry a high payload. In addition, our drivers should be able to sleep in the truck. For moving around construction sites, it is important that the vehicle has as much ground clearance as possible and can handle steep slope and ramp angles.”

For this reason, the road-oriented Actros 1843 LS with tipper trailer is designed to be best suited for transporting bulk goods predominantly on the road, with just the occasional off-road deployment.

What sets it apart from the long-distance Actros and the construction site Arocs is that while it is still an economical on-road specialist for long distances, it has been augmented in a targeted manner to make it fit for off-road operation as well. This advantage comes at the expense of only 70 kilograms in additional weight compared with the conventional Actros prime mover, and it is still up to 150 kilograms lighter than the comparable Arocs 4×2 LS.

To achieve this new configuration, the straight front axle of the Arocs was fitted into the road-oriented tipper trailer to give it greater ground clearance. The front spring hanger is made of robust steel, rather than aluminium. The construction site capable bumper corners made of steel and the optionally available movable entry also make it more robust and give greater freedom of movement on a construction site. The complete tipping hydraulic systems of the 4×2 and 4×4 prime movers are already available ex works. The two-line system can be switched from 250-bar high-pressure operation to low pressure at 170 bar, and it includes a backflow filter.

Thanks to the combined advantages of the Actros and the Arocs, the Geiger Group can now operate at the interfaces between construction sites and motorways with even greater flexibility.

Photos: Bernhard Huber

Comment

Please log in to post a comment.

4 comments

Ich wünsche euch noch viel Spaß damit 👍😀

LG Udo

Ich wünsche euch noch viel Spaß damit 👍😀

LG Udo